🧵 View Thread

🧵 Thread (57 tweets)

architect makes drawings, contractors bid price to complete. The less they actually spend, the more they pocket. This forces the architect to nail down millions of decisions before they can possibly be decided well, and makes sure the building is built as cheaply as possibly

in this system, it's expensive or impossible to make changes as you go along and you end up with crappy work Instead: a fixed amount within which the contractor is charged to make the most beautiful structure possible who controls the money and how makes all the difference https://t.co/CNgPSOWRlv

Christopher Alexander and his team at CES have developed contracts over the years that they use to approach this, can de dwnlaoded here: https://t.co/NboiC1mv6x

"The essence of a successful construction process — I have discovered over the years — is that the team working on a given part of a building have the satisfaction of working on a psychological whole and making it complete."

creation goals: https://t.co/9zUmx3hjyh

@aaronzlewis not just design tools, but materials themselves as the constraining factor in how things get made https://t.co/Q8v2geLABD

Two properties of materials that lend themselves to generative buidling process: https://t.co/W6cbVd78Ba

pre-industrial construction is often beautiful and life-supporting not because they were enlightened or better than us, but because the materials they used and the labor-material cost ratio lent itself to this stepwise generative building: bricks, plaster, mud, snow, stone

now labor costs are the majority of building costs, so new materials are needed that can allow for the adaptive building processes without intensive labor demands (printing with cement, growing mycelium structures, updated and tech-assisted earthen building)

ex: CONCRETE CANNON https://t.co/BH69jY5VRl

he drives home a point here: there's much attention to traditional building techniques, reviving old techniques, but that's not and can't be the future of construction: the cost of labor to do meticulous manual work as was done in the past just won't do

instead, we need new materials and new processes that revive not the particular materials and techniques, but the type of building process that those traditional ways required: step-by-step, continuously reacting to context, meticuluous attention to detail (NOT perfection)

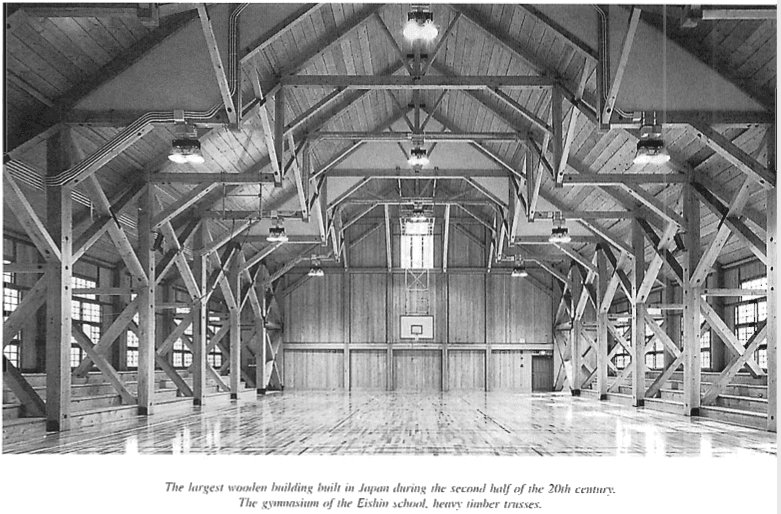

He talks about using heavy wood construction, great thick beams, as opposed to "cheaper" stud wall 2 by 4 frame construction He realized these heavy timber buildings would have lifetimes of several hundred years where the typical American frame house lasts maybe 40.

what are some experimental construction materials and techniques in the pipeline? SuperAdobe comes to mind https://t.co/EDsUYbrijt

this chair was printed from mycelium https://t.co/iV4Sk75iWr

more mycelium construction https://t.co/J2r4uYzjFI

hempcrete blocks https://t.co/MD3PhyjtxH

Now we're getting into the big stuff this is how we put the people to work and build American pyramids @wolftivy https://t.co/CPJlZn0W5Y

features of such a process: https://t.co/LdSsIsypUU

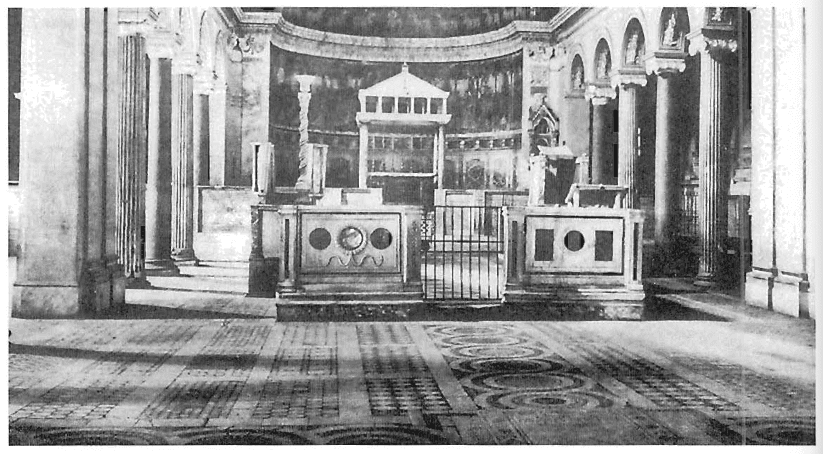

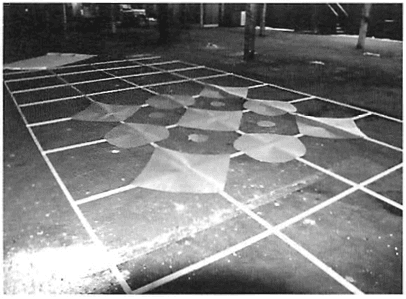

Case study: Christopher and his team were approached to create the marble floor for an expansion of the Megaron Concert Hall in Athens https://t.co/QaQABmGNLS

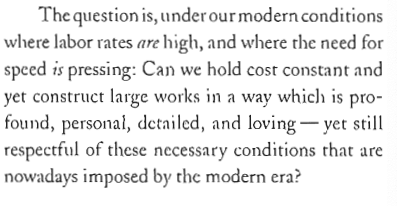

They wanted to recreate the amazing, custom, intricate marble floors of the ancient churches and halls of Rome: 8000 square meters of them to be precise (about two acres) The catch was this: they needed to be laid, ground, and polished months

The (much smaller) floors of the great churches often took years to produce, by many skilled craftsmen paintstakingly hand tooling thousands of individual marble pieces to fit the space and light perfectly. https://t.co/GfSX4NBl4D

It was this attention to detail and continuous adaptation that made those floors feel the way they do, gave them life. How could a floor of such magnitude be made at such speed without resorting to prefabricated, machined marble and sacrificing the life of the structure?

They needed to: 1. mockup the floor in 1:1 scale to determine the correct geometries of sections 2. cut thousands upon thousands of pieces of marble just-in-time as the design unfolds 3. prepare these pieces in their place in the design before they have access to the buidling

How they went about this: 1. booked a large warehouse in Oakland (near their offices) to lay out the floor in 2. divide the whole floor to be made into 100 sections, to be laid out sequentially in the warehouse 3. divide these sections into 100 sections to start with

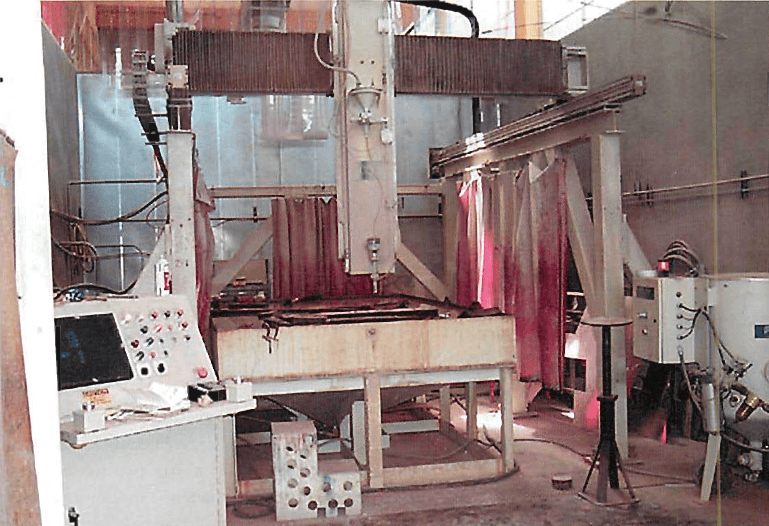

To cut such a volume of marble in reasonable time, they employed what was very new technology: a waterjet cutting machine that could cut rapidly and accurately from CAD models https://t.co/PySAlgDoag

Each section was mocked up then each of the smallest sections was laid out on fiberglass mats, to which the pieces were glued once in place. As they went, they constantly adapted pieces to look and feel good from all angles, using the waterjet to make fine adjustments as needed https://t.co/zkYEBxCJ3p

What this method allowed them do was marry the fine attention to detail and adaptation to context (though not AS fine as the manual work done in ages past) to a high speed and large scale process to work at the rate of modern construction. https://t.co/wZ3tFui6Yu

@JimmyRis I've been following some of the developments with aircrete, and I SO want to go to an aircrete dome-building & finishing workshop post-pandemic! https://t.co/6AloOcJhAo

back to top of Vision for a Living World thread (that I broke and continued here) https://t.co/M9mbxYaSjX